AC power high speed low pressure oil free Turbo Air Compressor

Features of Turbo Air Compressor

High Reliability

• GooDSeaA series centrifugal compressors are designed to be

extremely reliable due to:

• conservative high-quality gear design,

• long-life pinion bearing design,

• thrust loads absorbed at low speed,

• stainless steel compression elements

Low Compressor Operating Life Cycle Cost

GDC series centrifugal compressors provide better overall operating

efficiency than positive displacement compressors.

• Excellent efficiency at full load, part load and no load

• Low maintenance cost

• Increased uptime from high-reliability design (limits the need

for multiple unit installations for basic reliability reasons)

• No sliding or rubbing parts in the compression process that can

cause wear and thereby efficiency loss

Turbo Air Compressor Parameters

Model No. | GDC-30 |

Compressor Type | Centrifugal Type |

Stage No. | 1/2/3 |

Oil Free | Yes |

Service Life | ≥35years |

Anti-surge Function | Yes |

Power

(KW) | 130-270 |

Pressure

(bar) | 2.5-10 |

Air Flow

(m3/min) | 25-50 |

Dimension

(L*W*H )mm | 2750x1460x2000 |

Weight

(KG) | 4200 |

Impeller Material | Titanium Alloy/Stainless Steel |

Pinion Shaft Material | 17CrNiMo6 |

Bull Gear Shaft Material | 42CrMoA |

Motor | WEG/Marathon |

PLC Control System | Siemens |

Circuit Breaker | ABB |

Pressure Transducers | MEAS |

Temperature Control Valves | AMOT |

Vibration Sensors | Bently |

Temperature Sensor | SEC |

Motor Protection Grade | IP54 or customized |

Motor Insulation grade | F Class or customized |

Temperature Rise Leve | B Class or customized |

Lubrication Method | Grease Lubrication |

Standard 12inch LCD touch screen, all parameters can be viewed on

it, easy to operate;

Standard Siemens PLC, automatic dual mode + constant voltage

control mode can be switched locally and remotely to ensure safe

and stable operation;

Automatic remind when the faults occur or maintenance is needed;

Historical data can be viewed both locally and remotely.

Use centrifuge to replace many screw machines, save maintenance

cost & time and site area.

the larger volume, the higher efficiency. One centrifuge can save

about 25% energy when replacing several small screws.

Additional Technical Service Provided

Technical Service Provided for New Project: |

Customer Demand Learning - Equipment Selection - Solutions Evaluation - Engineering Design - Installation Guidance - Equipment Commissioning - After Sales Service

|

Technical Service Provided for Modified Project: |

Customer Demand Learning - Site Investigation - Equipment Selection - Energy Efficiency Saving Accounting - Solutions put into execution - Installation&Commissioning - Warranty Service

|

Our Service:

1. We aim to after-sales services globally.

2. Emails or calls for feedbacks in 2 months interval.

3. Installation guidance and on-site commissioning provided by

trained technicians or local authorised service crew.

4. Technical training provided in GooDSeaA Compressor factory or on

working site.

5. Genuine spare parts are available from our central stocks in

Shanghai and distributors' depots.

6. Technical documents in your language.

FAQ

Q: Are you a factory or trading company?

A: We are the professional air compressor/vacuum pump/ blower

manufacturer.

Q: Where does your company and factory locate in? How can I visit

you?

A: Our company locates in No.666, Xinbo Road, Maogang Town,

Songjiang District, Shanghai City 201606, China. It takes about one

hour from Shanghai Pudong airport or Hongqiao Airport to our

company.

Q: What does your company do regarding quality control?

A: Quality always enjoys the top priority. GoodSeaA attaches great

importance to quality control from beginning to the end.

Q: What is your after-sale service?

A: The guarantee period is 12 months from the date of the machine

installation or 15 months from the day of machine delivery. We will

take full responsibilities for the charges caused by the defects

during the guarantee period(This warranty does not cover human

damage or misuse of product).

Q: Do you offer consumables and wearing parts, too?

A: We supply all the necessary spare parts and wearing parts for

all equipments and on time.

Q: Which countries have you exported your products to?

A: Our group has been exporting our products to over sixty

countries, like Canada, the United States, Russia, Portugal,

Poland, Hungary, Turkey, South Africa, India, Singapore, the united

Arab Emirates, Egypt, Indonesia, Pakistan, Vietnam, Brazil, Peru,

Chile, Argentina etc.

Aeroengnine Compressor-Design and manufacture method

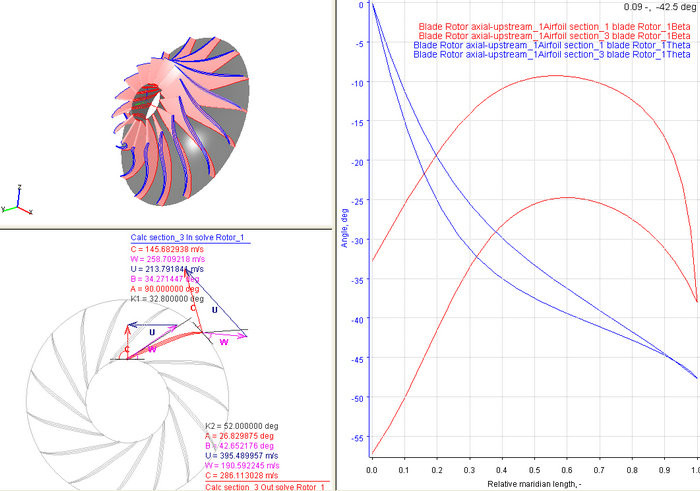

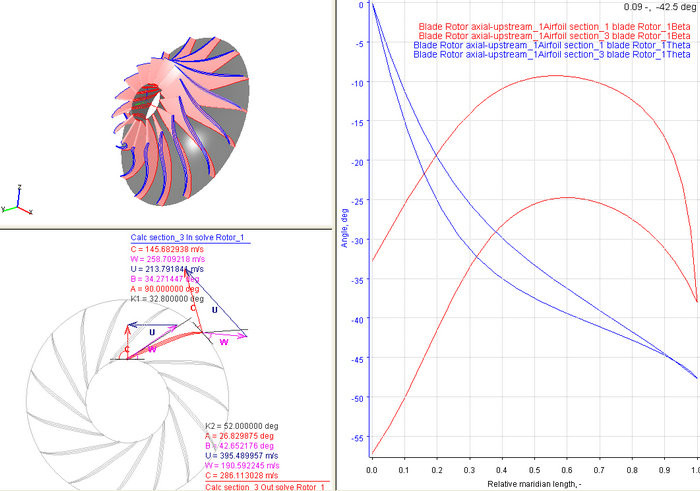

One-dimensional geometry and thermal design

AxStream design space - optimal performance point search

Two-dimensional flow design

Mainly refers to the meridional channel and streamlines design, and

the common meridional channel line is Bezier curve.

The design process focuses on the curvature change of the

streamline, the changes of blade mounting angle, or the area

shrinkage rate of the path.

The inlet and outlet mounting angle is given by the preliminary

design, while the position and size of the maximum blade mounting

angle are adjusted by the designer's experience and simulation

results.

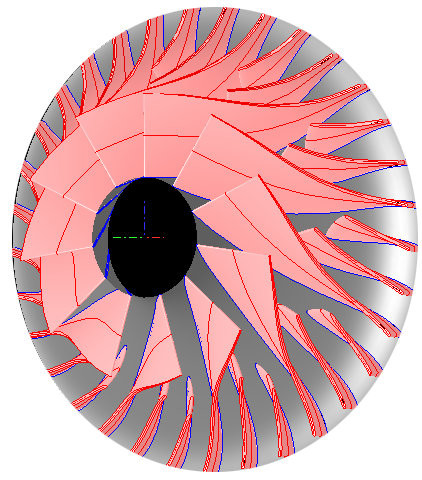

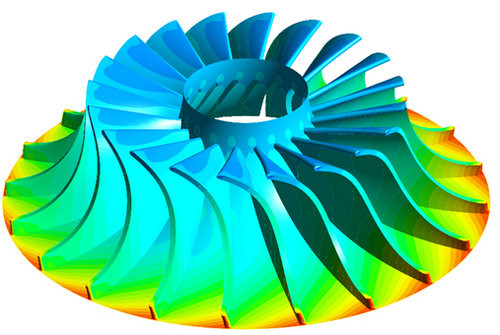

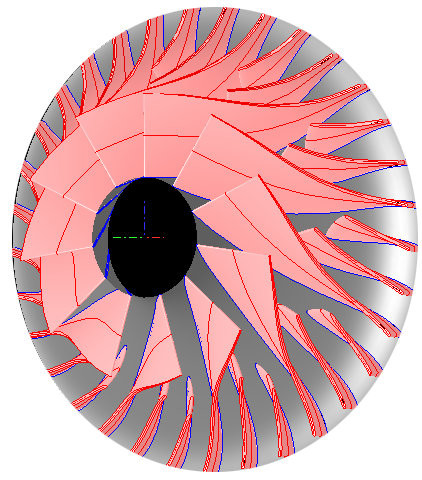

Three-dimensional blade design

The aero engine blades exhibit complex three-dimensional, complex

curved geometric features.

Using previous experience to design, or classic blade design can no

longer meet the needs.

The blade design, modeling and optimization process are mainly

accomplished by aero turbomachinery design software.

- The uses of splitter blades (also known as small blades) can not

only reduce the blockage of the impeller inlet, but also ensure

that the impeller has enough work function.

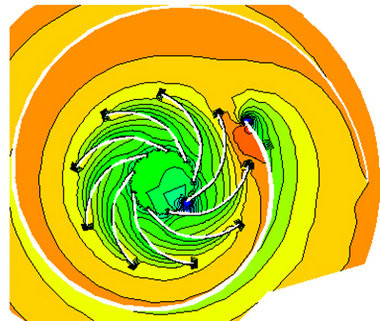

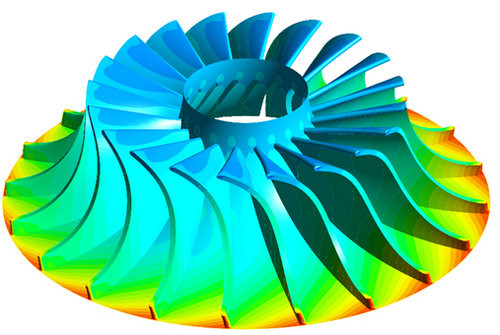

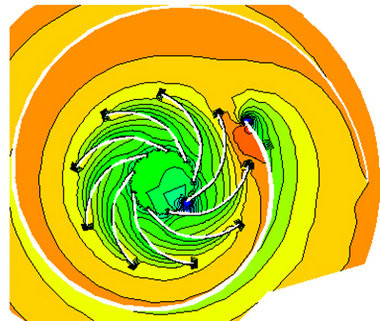

Three-dimensional flow field simulation

The aerodynamic calculation and full three-dimensional flow field

simulation are carried out by using the aviation aerodynamic

impeller ternary simulation software NUMECA to simulate the actual

operation and provide an important basis for design performance

evaluation.

Photos