Industrial Two Stage Oil free Turbine Air Compressor Capacity

78-140 m³/min GDC-90

Product Description

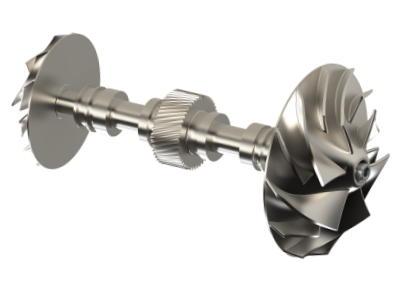

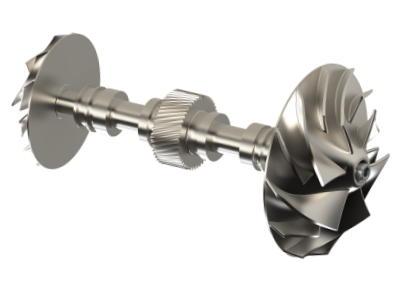

The centrifugal compressor unit consists of horizontally split

gearbox, high strength compressor casing, high performance titanium

alloy or 17-4PH hardened martensitic stainless steel impellers with

3-D flow backward leaning vanes, labyrinth gas and oil seal,

unitized, copper alloy cooler, inlet guide vanes with actuator and

fabricated baseframe supporting compressor, motor, cooler, control

cabinet etc and and lubrication oil tank.

Parameters

Model No. | GDC-90 |

Compressor Type | Centrifugal Type |

Stage No. | 1/2/3 |

Oil Free | Yes |

Service Life | ≥35years |

Anti-surge Function | Yes |

Power

(KW) | 430-800 |

Pressure

(bar) | 2.0-12 |

Air Flow

(m3/min) | 78-140 |

Dimension

(L*W*H )mm | 2950x1660x2100 |

Weight

(KG) | 4900 |

Impeller Material | Titanium Alloy/Stainless Steel |

Pinion Shaft Material | 17CrNiMo6 |

Bull Gear Shaft Material | 42CrMoA |

Motor | WEG/Marathon |

PLC Control System | Siemens |

Circuit Breaker | ABB |

Pressure Transducers | MEAS |

Temperature Control Valves | AMOT |

Vibration Sensors | Bently |

Temperature Sensor | SEC |

Motor Protection Grade | IP54 or customized |

Motor Insulation grade | F Class or customized |

Temperature Rise Leve | B Class or customized |

Lubrication Method | Grease Lubrication |

Features of Centrifugal Compressors

Integrated overall layout, compact structure, reasonable and simple

installation, only the air pipe, water pipe and electrical system

need to be connected.

The gearbox, bearing and sealing system are all of horizontal split

structure, which is convenient for maintenance. During maintenance,

it is not necessary to dismantle all the air inlet and exhaust

pipes, volute, etc. Compared with vertical sectioning, it can save

more than 6 times of maintenance time.

Equipped with imported regulating guide vane, it can save 9% energy

upon the maximum inlet flow than butterfly valve. Wide adjustment

range.

Efficient three-way flow backward curved impeller is adopted to

make the compressor reach 60-105% of flow regulation range. The

diffuser made of aviation aluminum material ensures no leakage and

minimal internal friction. Compared with cast iron, it has

corrosion resistance, high strength and small air resistance. The

efficiency of the compressor is further improved.

The advanced five piece tilting pad bearing, which has the

auto-center function ensures the best stable operation state,

excellent buffer performance, good anti oil film oscillation

performance, and the service life is more than 100000 hours. And

the designed service life of the unit shall not be less than 30

years.

GooDSeaA cooler structure adopts water flowing inside the pipe and

gas flowing outside the pipe , with guide rail and roller. The

drawable straight tube cooler is made of Navy copper, which has

excellent corrosion resistance and is not easy to scale.

Free switching parallel double oil filter effectively avoids the

disadvantage that the single oil filter must be shut down to

replace the filter element and extends its service life.

Two relatively independent working systems, air circuit and oil

circuit, ensure the air quality of compressor, and overcome the

leakage problem of compressor through reliable labyrinth seal or carbon

ring seal system.

Standard PLC + color LCD touch screen, with large storage function,

multiple monitoring and protection functions, can display multiple

information at the same time in the same picture, which is easier

to operate and more stable.

Through the advanced method of continuously monitoring the changes

of the two parameters of system pressure and current at the same

time, it can avoid the misoperation of surge only by single signal

judgment, and effectively prevent the occurrence of surge

Goodsea centrifugal compressor is equipped with vibration

measurement system in each stage of compression section, which has

protection measures for each stage. And the equipment has the

functions of numerical display, alarm, shutdown, etc. Ensure safe

and stable operation of the whole set machine.

Impeller

Impeller Type | 3-D flow backward leaning vanes |

Material | Aircraft-grade titanium alloy or high strength stainless steel |

Volute

Split Type | Horizontal |

Material | Ductile Cast Iron |

Pinion

Bearing Type | 5-petal tilting-pad type bearing |

Shaft Type | With thrust ring |

Shaft Material | 17CrNiMo6 |

Grade | AGMA 13 |

Big gear wheel

Bearing Type | Radial direction thrust bearing |

Shaft Material | 42CrMoA |

Big gear wheel | 17CrNiMo6 |

Grade | AGMA 13 |

FAQ

Q: Are you a factory or trading company?

A: We are the professional air compressor/vacuum pump/ blower

manufacturer.

Q: Where does your company and factory locate in? How can I visit

you?

A: Our company locates in No.666, Xinbo Road, Maogang Town,

Songjiang District, Shanghai City 201606, China. It takes about one

hour from Shanghai Pudong airport or Hongqiao Airport to our

company.

Q: What does your company do regarding quality control?

A: Quality always enjoys the top priority. GoodSeaA attaches great

importance to quality control from beginning to the end.

Q: What is your after-sale service?

A: The guarantee period is 12 months from the date of the machine

installation or 15 months from the day of machine delivery. We will

take full responsibilities for the charges caused by the defects

during the guarantee period(This warranty does not cover human

damage or misuse of product).

Q: Do you offer consumables and wearing parts, too?

A: We supply all the necessary spare parts and wearing parts for

all equipments and on time.

Q: Which countries have you exported your products to?

A: Our group has been exporting our products to over sixty

countries, like Canada, the United States, Russia, Portugal,

Poland, Hungary, Turkey, South Africa, India, Singapore, the united

Arab Emirates, Egypt, Indonesia, Pakistan, Vietnam, Brazil, Peru,

Chile, Argentina etc.

Product Photos