45-95 m³/min High-Efficient bearing-levitation centrifugal blower

Introduction

Maglev blower is a new type of blower, which uses the technology of

Maglev bearing to eliminate friction completely and improve the

mechanical performance of blower fundamentally. Compared with the

traditional fans, maglev blower has the advantages of high

efficiency, energy saving, low noise, convenient installation,

structure integration, high cooling efficiency, low maintenance,

convenient remote control, which can ensure the running stability

of the sewage treatment plant and reduce the system replacement

cost, so it is favored by many users and preferred by many

contractors.

Blower is the common equipment of sewage treatment plant at present

and the main energy consumption equipment. Traditional fans have

disadvantages of high energy consumption and very loud noise, which

not only increases the operating cost of sewage treatment plant,

but also causes noise pollution around. While the magnetic

suspension single-stage high-speed centrifugal blower has the

advantages of high efficiency, less space demand, wide range of

flow regulation, high level of automation, and now has been widely

used.

Technical Principle

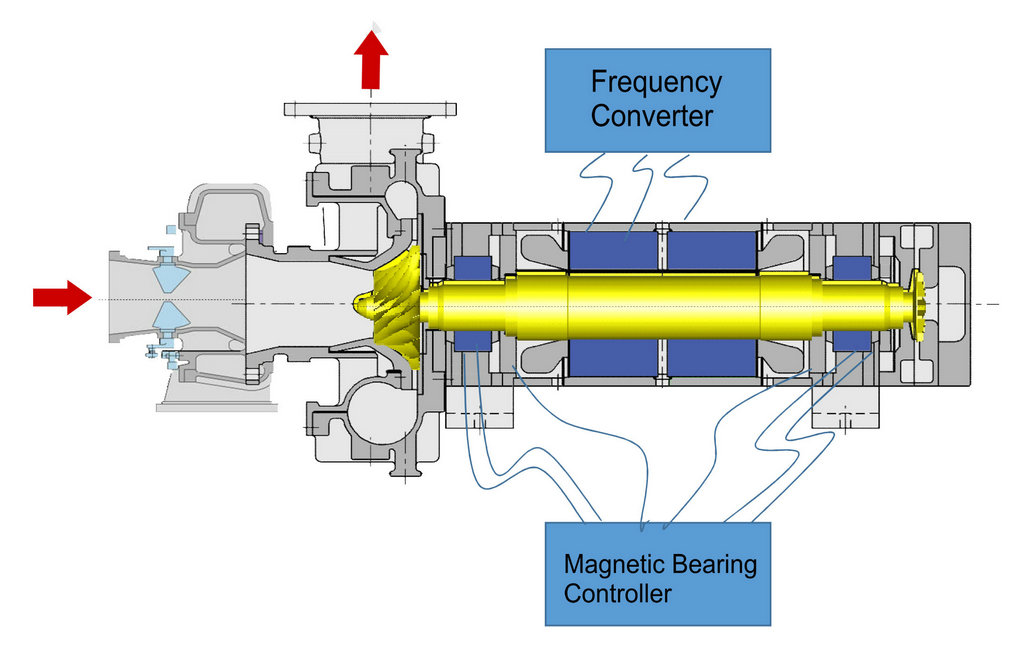

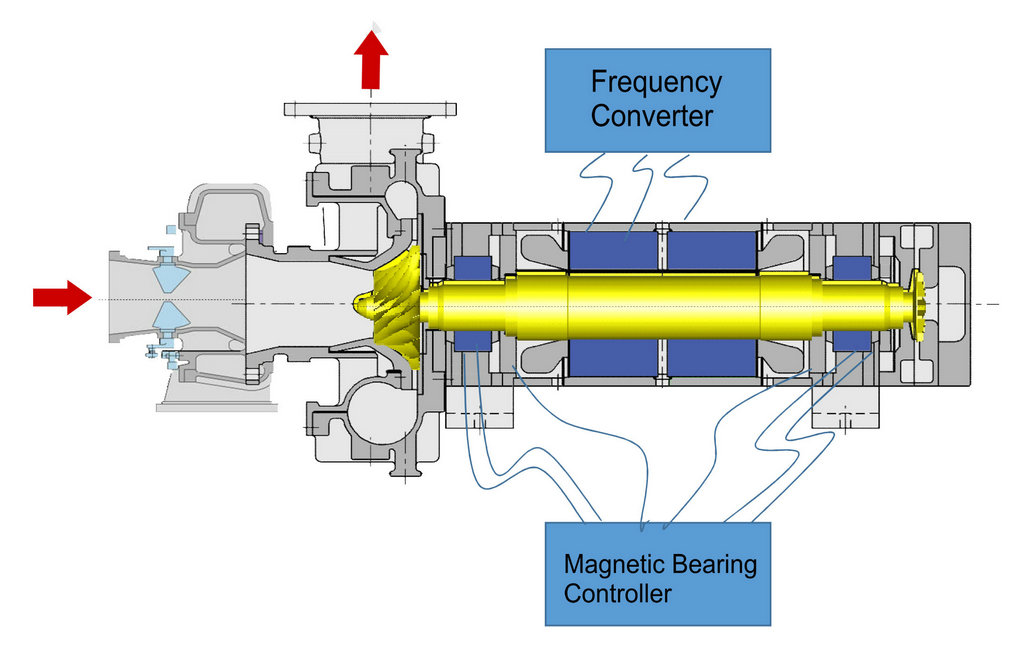

Magnetic suspension bearing, also known as electromagnetic bearing,

replaces the traditional mechanical bearing through a kind of

technology of magnetic force by levitating the rotor. The rotor of

the magnetic bearing is ferromagnetic, which keeps relative balance

and levitation under the action of gravity through the attraction

of the upper and lower combined iron batteries; when the external

force interferes, the rotor deviates from the original suspension

center, and the displacement of the rotor relative to the balance

center is detected by the sensor, and the electric state signal

which is formed after being sampled by the signal A/ D is

transmitted to the controller.

The high-speed computation device in the controller generates

real-time control signals after pre-set control logic algorithm

calculation, that makes the electromagnetic force on the

electromagnet to compete with the external force, and makes the

rotor return to the suspension center for continuous and stable

operation. At the same time, the bearing accurately controls the

rotor axis position with more than 10000 times signal acquisition

per send and real-time correction, and the axis deviation is

controlled within 10 μ m. With the self balancing technology, the

vibration is much less than that of the traditional bearing.

Product feature

By using frequency conversion to adjust output parameters and

non-contact rotation, it can effectively save energy and reduce

operation and maintenance costs.The equipment is small in volume,

light in weight and easy to install and operate. Low noise and no

vibration during operation.

Multiple business modes available

Direct Manufacturer

Looking for distributors to help market our products

OEM Service

EMC

Equipment Renting

......

Parameters of Magnetic bearing-levitation centrifugal blower

MODEL | Power KW | Pressure Kpa | Air Flow m3/min | Outlet Connection | DIMENSION L*W*H mm | WEIGHT KG |

GDE75-04 | 75 | | 95 | DN300 | 1780x860x1560 | 800 |

GDE75-06 | 60 | 66 | DN200 |

GDE75-08 | 80 | 53 |

GDE75-09 | 90 | 45 |

GDE100-04 | 100 | | 120 | | 1980x1050x1750 | 1050 |

GDE100-06 | 60 | 85 |

GDE100-08 | 80 | 68 | DN200 |

GDE100-10 | 100 | 55 |

GDE150-04 | 150 | 40 | 180 | | 2080x1150x1850 | 1150 |

GDE150-05 | 50 | 150 |

GDE150-06 | 60 | 138 |

GDE150-07 | 70 | 118 |

GDE150-08 | 80 | 109 | DN250 |

GDE150-09 | 90 | 90 |

GDE200-04 | 200 | 40 | 236 | | 2280x1300x2000 | 1450 |

GDE200-05 | 50 | 192 |

GDE200-06 | 60 | 162 | DN300 |

GDE200-07 | 70 | 150 |

GDE200-08 | 80 | 135 |

GDE200-09 | 90 | 115 |

GDE200-10 | 100 | 108 |

GDE200-12 | 120 | 100 |

GDE300-05 | 300 | 50 | 288 | DN500 | 3080x1650x2100 | 2050 |

GDE300-06 | 60 | 270 |

GDE300-08 | 80 | 215 | DN400 |

GDE300-10 | 100 | 172 |

GDE300-12 | 120 | 130 | DN300 |

GDE300-15 | 150 | 110 |

GDE400-05 | 400 | 50 | 392 | DN600 | 3350x1850x2200 | 2360 |

GDE400-06 | 60 | 335 |

GDE400-08 | 80 | 270 | DN500 |

GDE400-10 | 100 | 230 |

GDE400-12 | 120 | 195 | DN400 |

GDE400-15 | 150 | 160 |

Remarks 1.Above Design Parameters are obtained based on below conditions: We assume the inlet volume flow is defined as the standard of 20℃ suction temperature and 1atm 2.We reserve the right to update the referred contents. Some

parameters can be changed according to the actual needs. Please refer to the pre-sale service. |