345 m³/min High Power Centrifugal Vacuum Pump - the Great

Substitute for Water Ring Vacuum Pump

Description

GoodSeaA high-speed variable frequency centrifugal vacuum pump

adopts aerodynamic technology and aviation-grade processing and

manufacturing process, it is designed for the papermaking and

chemical industries. The impeller adopts aviation-grade

high-strength alloy material, which can be used 300,000 hours

(about 35 years) without maintenance. It’s drive system uses

high-efficiency and energy-saving motors, the quality is stable and

reliable, It is suitable for long-term stable operation in harsh

environments such as high temperature and high humidity.

According to the characteristics of papermaking industry, the

impeller of the centrifugal vacuum pump is specially made of

aviation-grade high temperature-resistant and high strength alloy

material, abrasion resistance, corrosion resistance, white water

droplets resistance and pulp fiber impact resistance, able to provide 30 years of service, impeller maintenance free.

In the process of design and R&D, special attention is paid to

the high performance, high reliability and high cost performance of

the product.

Compared with the advanced turbine vacuum pump abroad, the

transformation cost can be saved by more than 50% for machines of

the same power.

The advantages of centrifugal vacuum pump compared with water ring

pump

Item | Water ring pump | Centrifugal vacuum pump |

Cost Performance | Its low efficiency and high power consumption makes its comprehensive use cost high in spite of its low manufacturing cost | Its high efficiency makes its comprehensive use cost low even the manufacturing cost is high |

Technology Advancing Level | Low | High |

Average Service Life | 3-5 years | 10-20 years |

Efficiency | Polytropic efficiency | Adiabatic efficiency 80%~90% |

Quality | Poor operational reliability | Great operational reliability, aviation-grade material |

Final Vacuum | -98kPa | For Single stage: -65kPa For Double stage:-85kPa |

Applicable Situation | Low flow rate, high vacuum degree(above -70kPa) | High flow rate,stable vacuum degree(-30 ~ -75kPa) |

Conversion of power and flow | 100kW=60~86m3/min | 100kW=110~120m3/min |

Aeroengnine Compressor-Design and manufacture method

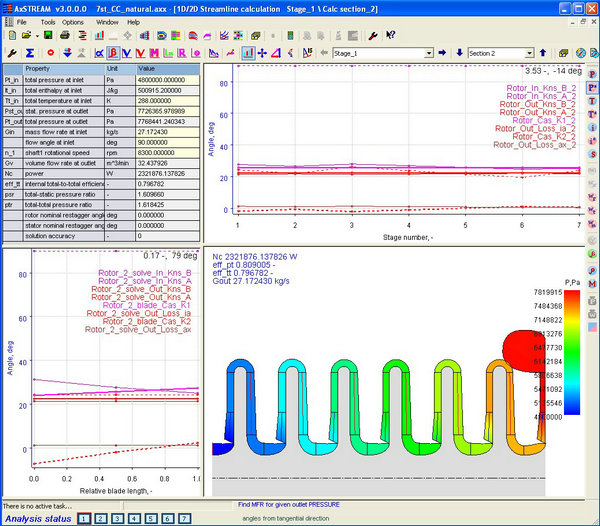

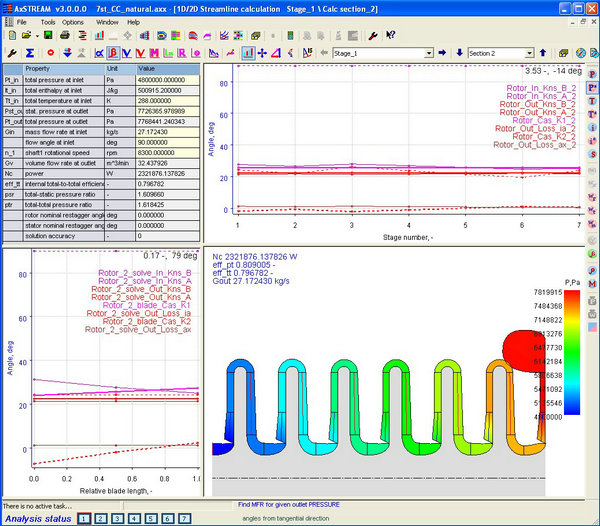

One-dimensional geometry and thermal design

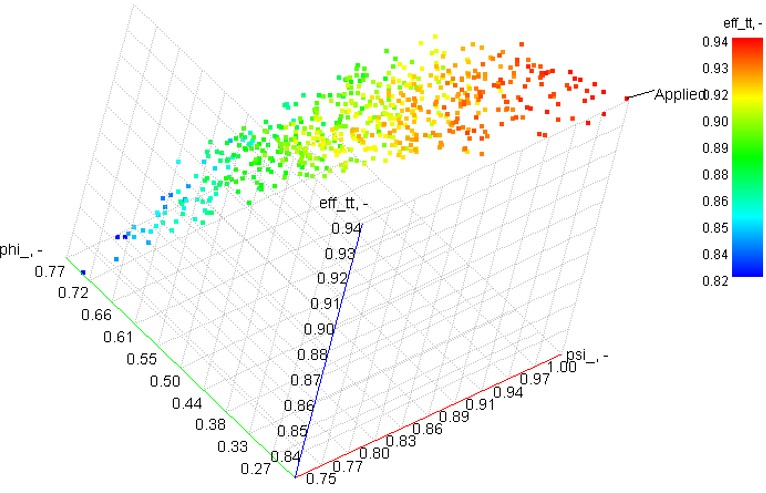

AxStream design space - optimal performance point search

Two-dimensional flow design

Mainly refers to the meridional channel and streamlines design, and

the common meridional channel line is Bezier curve.

The design process focuses on the curvature change of the

streamline, the changes of blade mounting angle, or the area

shrinkage rate of the path.

The inlet and outlet mounting angle is given by the preliminary

design, while the position and size of the maximum blade mounting

angle are adjusted by the designer's experience and simulation

results.

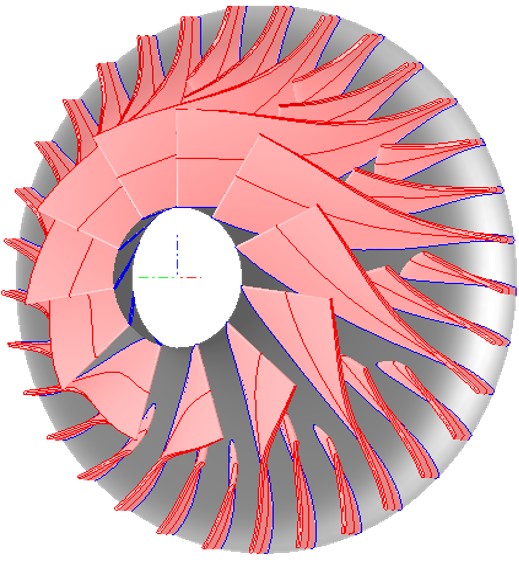

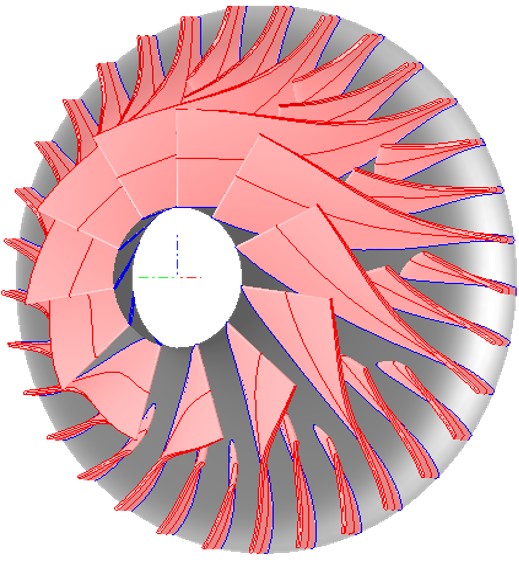

Three-dimensional blade design

The aero engine blades exhibit complex three-dimensional, complex

curved geometric features.

Using previous experience to design, or classic blade design can no

longer meet the needs.

The blade design, modeling and optimization process are mainly

accomplished by aero turbomachinery design software.

- The uses of splitter blades (also known as small blades) can not

only reduce the blockage of the impeller inlet, but also ensure

that the impeller has enough work function.

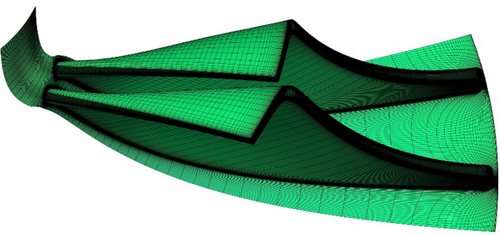

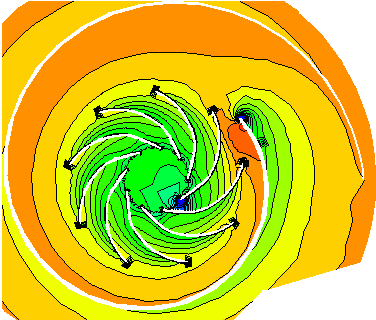

Three-dimensional flow field simulation

The aerodynamic calculation and full three-dimensional flow field

simulation are carried out by using the aviation aerodynamic

impeller ternary simulation software NUMECA to simulate the actual

operation and provide an important basis for design performance

evaluation.

Commissioning & Testing

1. High Speed Dynamic Balance Test

Gradually balancing from low speed to high speed.

The equilibrium speed is as close as possible to the critical

speed.

Balance at rated working speed to ensure balance accuracy.

2. Rotor Test

The wheel rotation fracture test is carried out without damage in

the ground with 122% maximum rotational speed.

Working on the engine at 115% maximum allowable steady-state

operating speed for 5 minutes without cracking and the size is

within the allowable range.

On the engine, exceed the maximum allowable average steady-state

temperature of 42℃, work for 5 minutes without cracking, and the

size is within the allowable range.

3. Vibration Test

20% margin between critical speed and maximum working speed.

During the test of the components and the whole machine, there is

no adverse reaction to the vibration in the working speed range.

4. Performance, Characteristic Test

Performance tests under design conditions.

Characteristic tests under non-design conditions.

Process the test data to determine whether the performance of the

component is up to standard and draw a characteristic curve.

Values Made for Customers

Provide customized design according to user’s paper machine vacuum

system, enables the equipment always working in energy-efficiency

area, which can save 30-60% energy and 100% water for the

papermaking vacuum system. Through the waste heat recovery system,

the level of comprehensive energy utilization will be further

improved. The investment recovery period is 8-18 months. One unit

500kW centrifugal vacuum pump can at least completely replace the

water ring vacuum pump with a total power of 710kW. Each production

line can save 200 Thousand Dollars in electricity for cusomters per year.

Saving money means making money. After adopting our company's

vacuum pump instead of it’s old water ring pump, one listed

papermaking enterprise realized energy saving of 50% and increased

production by 20% under the condition that other parts of the paper

machine remained unchanged. Our vacuum pump has create the value of

20 Million Dollars every year for this papermaking company.

No need for grid expansion and space saving. With frequency

conversion starting, and there is no impact on the power network.

Compared with traditional vacuum systems, this equipment saves more

than half of space.

Below Chart: Power saving data of GooDSeaA centrifugal vacuum in

one year

(The equipment works 24 hours per day, 300 days per year, and the

electricity cost is calculated as 0.7 CNY/kWh.)

Installed Power(KW) | 500 | 1000 | 1500 | 2000 | 2500 | 3000 |

Water Ring Pump Efficiency | Energy Saving | Electricity costs saved which is equivalent to net profit get (Unit: $10Thousand) |

30% | 60% | 151.2 | 302.4 | 453.6 | 604.8 | 756 | 907.2 |

33% | 56% | 141.12 | 282.24 | 423.36 | 564.48 | 705.6 | 846.72 |

36% | 52% | 131.04 | 262.08 | 393.12 | 524.16 | 655.2 | 786.24 |

39% | 48% | 120.96 | 241.92 | 362.88 | 483.84 | 604.8 | 725.76 |

42% | 44% | 110.88 | 221.76 | 332.64 | 443.53 | 554.4 | 655.28 |

45% | 40% | 100.8 | 201.6 | 302.4 | 403.2 | 504 | 604.8 |

48% | 36% | 90.72 | 181.44 | 272.16 | 362.88 | 453.6 | 544.32 |

Parameters of High-Speed VF Centrifugal Vacuum Pump

MODEL | Motor Power KW | Shaft Power KW | Air Flow m3/min | Vacuum Degree Kpa |

GDV110 | 110 | 95.3 | 120 | -50 |

GDV160 | 160 | 139.1 | 175 | -50 |

GDV200 | 200 | 174.7 | 220 | -50 |

GDV250 | 250 | 217.4 | 275 | -50 |

GDV280 | 280 | 246.1 | 310 | -50 |

GDV315 | 315 | 273.9 | 345 | -50 |

GDV355 | 355 | 309.6 | 390 | -50 |

GDV400 | 400 | 349.3 | 440 | -50 |

GDV450 | 450 | 396.9 | 500 | -50 |

GDV500 | 500 | 436.7 | 550 | -50 |

GDV560 | 560 | 484.3 | 610 | -50 |

Remarks 1.Above Design Parameters are obtained based on below conditions: Suction Medium: Air, Relative Humidity: 65%, Suction Air

Temperature: 35℃, Discharge Pressure: 101.3kPaA 2.For special working conditions or vacuum condition changes, the

vacuum pump can be designed according to actual demands. Please refer to pre-sale service. |