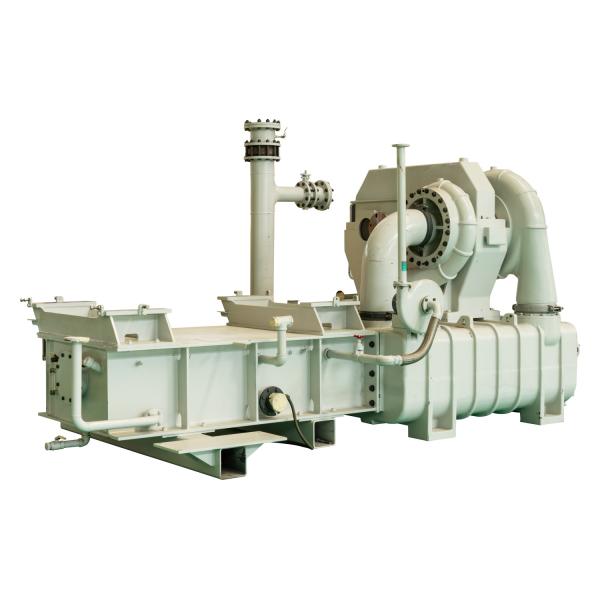

Industrial Centrifugal Type Gas Turbo Compressor

Product Description

The GDC series oil-free centrifugal air compressor is designed to

ensure the continuous and stable operation under a wide range of

large gas flow working condition. Its high working efficiency can

fully meet the gas supply demand of various process flow and

provide absolutely oil-free high-flow compression for all

industries. The precisely designed impeller and diffuser ensure

that the compressor can work efficiently in a wide range of gas

volume.

Parameters

| Model No. | GDC-30 |

| Compressor Type | Centrifugal Type |

| Stage No. | 1/2/3 |

| Oil Free | Yes |

| Service Life | ≥35years |

| Anti-surge Function | Yes |

Power

(Kw) | 150-270 |

Pressure

(bar) | 2.0-10 |

Air Flow

(m3/min) | 25-50 |

Dimension

(L*W*H )mm | 2750x1460x2000 |

Weight

(KG) | 42000 |

| Impeller Material | Titanium Alloy/Stainless Steel |

| Pinion Shaft Material | 17CrNiMo6 |

| Bull Gear Shaft Material | 42CrMoA |

| Motor | WEG/Marathon |

| PLC Control System | Siemens |

| Circuit Breaker | ABB |

| Pressure Transducers | MEAS |

| Temperature Control Valves | AMOT |

| Vibration Sensors | Bently |

| Temperature Sensor | SEC |

| Motor Protection Grade | IP54 or customized |

| Motor Insulation grade | F Class or customized |

| Temperature Rise Leve | B Class or customized |

| Lubrication Method | Grease Lubrication |

Application Fields

Centrifugal compressors are widely used in large-scale chemical

industry, oil refining, metallurgy, oxygen production,

pharmaceutical and other fields because of their outstanding

advantages. It plays an important role in the relevant production

equipments, and is known as the "heart" of the production line.The

GDC series oil-free centrifugal air compressors are uniquely

designed to ensure continuous and stable operation over a wide

operating range. Their efficient operating efficiency meets the gas

supply requirements of various process flows, providing absolutely

oil-free high-flow compression for all industries.

Features of Centrifugal Compressors

Centrifugal compressors are now being widely used in many fields,

such as Chemical and Petrochemical, Midstream, Fertilizer, Power

Generation, Industrial Gases, Textile Industry, LNG industry, this

is mainly because it has below advantages compared with piston

compressors:

1. The centrifugal compressor has a large gas volume, simple and

compact structure, light weight, small unit size and small floor

space.

2. the operation is balanced, the operation is reliable, the

operation rate is high, and the friction parts are few, because the

spare parts need less usage, the maintenance cost and the personnel

are small.

3. In the chemical process, the centrifugal compressor can achieve

an absolutely oil-free compression process for chemical media.

4. The centrifugal compressor is a kind of rotary motion machine,

which is suitable for direct dragging of industrial steam turbines

or gas turbines.For general large-scale chemical plants, it is

often used as a by-product steam-driven industrial steam turbine to

provide power for comprehensive utilization of thermal energy.

Models

MODEL | POWER KW | PERSSURE

bar | AIR FLOW

m3/min | DIMENSION

L*W*H mm | WEIGHT

KG |

GDC-30 | 130-270 | 2.5-10 | 25-50 | 2750x1460x2000 | 4200 |

GDC-60 | 260-450 | 2.5-10 | 48-85 | 2850x1560x2000 | 4500 |

GDC-90 | 430-800 | 2.5-10 | 78-140 | 2950x1660x2100 | 4900 |

GDC-120 | 710-1050 | 2.5-10 | 132-200 | 3000x1660x2120 | 8100 |

GDC-150 | 980-1500 | 2.5-10 | 180-270 | 4800x2200x2600 | 12000 |

GDC-250 | 1500-1900 | 2.5-10 | 270-360 | 5300x2600x3000 | 18000 |

GDC-400 | 1960-2900 | 2.5-10 | 360-530 | 5800x3000x3200 | 28000 |

GDC-650 | 2600-4900 | 2.5-10 | 470-890 | 6200x3500x3800 | 48000 |

GDC-1200 | 4500-9100 | 2.5-10 | 830-1500 | 7200x5000x4800 | 53000 |

Brand of Main Components of Machine

| Motor | WEG/Marathon |

| PLC Control System | Siemens |

| Circuit Breaker | ABB |

| Pressure Transducers | MEAS |

| Temperature Control Valves | AMOT |

| Vibration Sensors | Bently |

| Temperature Sensor | SEC |

| ...... | ...... |

Advantages

1. 100% Oil-free

Perfect separation structure between the lubricating oil part and

the air compression part ensures 100% clean and oil-free compressed

air.

2. Anti-surge control system

The system consists of surge pressure sensor and motor current

sensor. When the change ratio of the last stage exhaust pressure

and the change ratio of the motor current is higher than the set

value of surge, PLC will regard this situation as surge, and then

alarming system will work and compressor will stop meanwhile

discharging the air. Through the advanced method of continuously

monitoring the changes of the two parameters of system pressure and

current at the same time, it can avoid the misoperation of surge

only by single signal judgment, and effectively prevent the

occurrence of surge.

3. Wide range of applications

Compressors from single stage to multiple stages (6 stage) are all

available, we provide customized products.

4. Durability

Stable quality assurance system to insure the compressor

performance

The modern industrial craft adopted in impeller making

The centrifugal air compressor is developed through the cooperation

between domestic top experts in aviation air dynamics and GoodSeaA

research team. The key part of the centrifugal air compressor is

impeller, which is designed with the advanced aero-engine design

software Axstream, verified with the aero-engine strength

verification software ANSYS and processing on 5-axis CNC machine. During the making process, the three dimention flow field simulation is carried out by using

aerodynmic impeller simulation softwere NUMECA.

High-Speed Centrifugal Compressor Design Case

- Design Tools:

Based on“AxStream-AutoGrid-Numeca-Isight”design platform

Computed Field Grids(with Vaneless Diffuser) Numerical Analysis

Results -Static Pressure

Product Photos